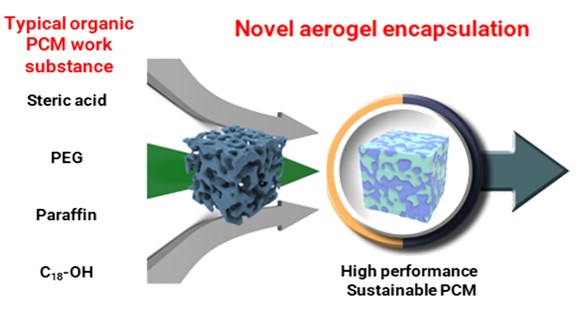

In recent years, the increasingly prominent energy and environmental problems have created an urgent need to develop tools that allow a more efficient use of energy. Regarding this, thermal energy storage technologies are essential components in many systems and also a considerable option in order to achieve a transition to low-carbon industries. Phase-change materials (PCMs) are a thermal energy storage tool useful when energy has to be stored or released within a narrow temperature range, as well as in situations when compactness is required. However, the use of these materials also present some drawbacks, such as the need of encapsulating solid-liquid PCMs to prevent the leakage of the liquid phase.

In order to solve these problems, researchers from Universidad Francisco de Vitoria (UFV) and IMDEA Materials Institute have developed a novel composite phase-change material based on an aerogel.

The researchers have developed an improved composite phase-change material that is based on an aerogel made of polylactic acid (PLA). This PCM has a porosity of 90% approximately and acts as a scaffold for the solid-liquid phase-change material. The composite developed by the researchers presents phase change enthalpies of 100-250 J/g and can operate within different ranges of temperature depending on the phase change material used, comprising values that go from 40 up to 200ºC. Furthermore, the composite manufacturing process allows the possibility to include additives in the formulation, thus protecting the system from external environments.

A European patent application has already been presented for this technology. The current TRL for the invention is 3, and the researchers are already working on scaling up the process. They are also performing assays specific to different industries in order to increase its maturity level.

Benefits:

- Versatile technology, providing different parameters depending on the composite PCM formulation.

- It allows to bypass some obstacles associated with similar technologies used currently, such as phase separation phenomena and sedimentation problems.

- Suitable for its implementation in various industries, such as electronics manufacturing and energy storage.

- It presents optimized parameters, such as ultra-high latent heat and form stability.

- Some parameters such as thermal conductivity and fire safety can be enhanced by adding corresponding functional fillers to the PCM.

The represented institution is looking for a collaboration that leads to commercial exploitation of the presented invention.

Institution: Universidad Francisco de Vitoria, Instituto IMDEA Materiales

TRL: 4

Protection status: Patent Application

Contact: Carlos G. Gredilla / c.gredilla@viromii.com