Improvements made in the petrochemistry field are highly desirable for the companies involved due to the operative costs associated with power consumption or materials such as catalysts. In the case of the reductive hydroformylation of ethylene with syngas to obtain 1-propanol, the current process requires a gas-liquid operation and molecular catalysts in solution to preserve high selectivity values. However, it is difficult to isolate the product and recover the catalyst from the solvent stream.

To solve this, researchers from the ITQ (Instituto de Tecnología Química UPV-CSIC) have developed a process that provides a gas-solid conversion route with very high selectivity to 1-propanol. The process employs exclusively a combination of solid catalysts which converts a gaseous stream, e.g. in a fixed-bed reactor, hence directly avoiding those issues associated to the recovery of expensive organometallic catalysts (such as those based in elements like rhodium or ruthenium) from liquid media.

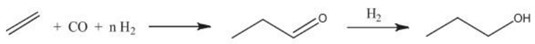

The developed process is a reductive hydroformylation with syngas of ethylene to produce 1-propanol. Via hydroformylation, a C3 aldehyde (propanal) is obtained from a C2 olefin. Sequentially, in the same reactor, propanal hydrogenation renders a C3 1-alcohol (1-propanol) in a single conversion step.

Potential benefits:

For its possible applications, the process implementation can provide the following potential benefits:

- Reactive separation of ethylene from ethane: Less energy required to perform this reaction.

- Propylene production: Valorization of ethylene to obtain propylene, a more demanded compound.

- The reaction works under standard operating conditions. Therefore, it can be implemented in already existing systems.

- The catalyst is solid, it is not necessary to recover it from the product and waste flows.

Stage of development:

Patent applications have already been requested for this technology. The current TRL of the invention is TRL 4 since it has been already tested in the laboratory.

The represented institution is looking for a collaboration that leads to commercial exploitation of the presented invention.

Institution: Asociación RUVID & Instituto de Tecnología Química UPV-CSIC

TRL: 3-4

Protection status: Patent Application

Contact: Pablo Lago / pablo@viromii.com