In current industrial processes across diverse industries, viscoelasticity characterization is a key process to determine materials’ behavior. However, these properties are often challenging to measure, mainly because they require specialized, bulky, and expensive equipment. In addition, they also need to be operated by highly trained professionals. These obstacles have created a need to develop tools that allow this type of analysis to be carried out more easily, avoiding excessive costs in specialized equipment and facilitating integration with production processes.

To solve this problem, researchers from the University of Barcelona have developed MIRANDA, a software tool to extract and characterize material viscoelasticity through the analysis of images acquired with a high-speed camera.

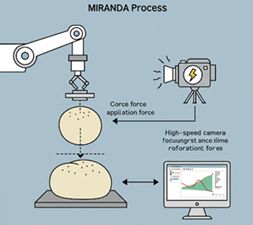

The system developed by the research team offers a non-invasive software platform for the detailed analysis of viscoelastic properties. The developed software operates by detecting movement patterns after stress has been imposed on the material and subsequently released. Once high-resolution images are captured, the program deploys sophisticated algorithms, in combination with robotics, to process live pictures and extract data on shape, texture, and intricate viscoelastic properties of the material. MIRANDA allows for a real-time evaluation of material responses to external forces, enabling the optimization of production processes and ensuring stringent quality control in manufacturing.

The research team has already validated the efficiency of MIRANDA at a lab scale, having proved its accuracy to test materials such as different types of bread, viscoelastic putty, sponges and kinetic sands. These proof-of-concept tests have demonstrated its ability to generate highly accurate quantitative data on viscoelastic properties and motion dynamics. Furthermore, the researchers are currently assembling a prototype of a robotic arm to apply reproducible forces to tested materials.

Benefits:

- Offers a cost-effective, real-time solution, eliminating the need for bulky and expensive equipment.

- Generates highly accurate and reproducible quantitative data on viscoelastic properties and motion dynamics.

- Provides precise evaluation of elasticity, viscosity, relaxation, and creep behavior of a wide range of viscoelastic materials.

- It allows for discrete or continuous analysis in production lines, providing easy integration in defined industrial processes.

The represented institution is looking for a collaboration that leads to commercial exploitation of the presented invention.

Institution: Universitat de Barcelona

TRL: 4

Contacto: Carlos G. Gredilla / c.gredilla@viromii.com