The recycling of multi-component textile products, such as footwear, carpets or technical textiles, presents great difficulties due to the use of permanent hot melt adhesives that prevent the separation of the different materials without damaging them. This limitation makes disassembly at the end of the product’s useful life unfeasible, makes recycling processes more expensive and causes most of this waste to end up in landfill or incineration. In addition, current systems require high energy consumption and do not allow the recovery of high-value materials. In a context of increasing regulatory pressure and demand for circular solutions, the textile industry needs bonding technologies that maintain performance in use, but allow for clean, efficient and controlled disassembly at the end of the product life cycle.

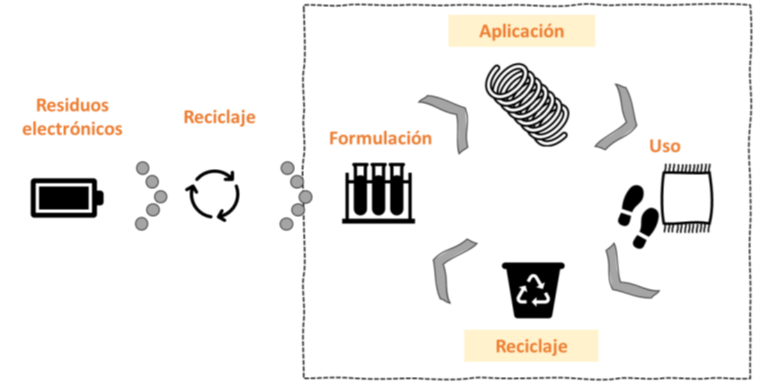

The technology developed by AITEX is based on a new generation of additive hot melt adhesives with reversible bonding capacity. These adhesives can be custom-formulated and selectively heated using non-contact heating technologies, such as induction. Direct heating allows the adhesive to be melted both during the bonding phase and at the end of the product’s useful life, making it possible to disassemble without damaging the bonded materials or degrading the additives. The formulation incorporates functional fillers, such as magnetite and carbon nanotubes, which improve thermal efficiency, reduce the amount of additives needed and make it possible to take advantage of materials recovered from electronic waste, reinforcing the circular economy approach.

The technology has been functionally validated at the laboratory and proof-of-concept level, focusing on its implementation in pilots and industrial demonstrators.

Benefits:

- Enables safe and efficient disassembly of complex textile products.

- It significantly reduces the energy required in the application and separation of the adhesive.

- Improves initial adhesion thanks to direct induction heating.

- It keeps the adhered materials intact, favoring their reuse.

- It reduces the amount of technical additives required thanks to the magnetite-carbon nanotube synergy.

- It enhances the circular economy through the possible use of metals recovered from electronic waste.

The development team is looking to establish strategic collaborations that will allow this technology to be brought to market in the near future. The conditions and form of collaboration can be openly discussed if the technology presented is of interest.

Institution: Asociación de Investigación de la Industria Textil (AITEX)

TRL: 3-4

Protection Status: Know-how / Methodology

Contacto: Begoña Iborra / biborra@viromii.com